|

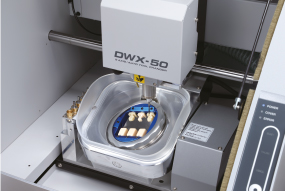

桌上型 5 軸高精度雕刻機

DWX50(自動換刀

5 把刀)

累積

20 年銑削的加工技術,日本 Roland

公司擘劃推出新世代的桌上型 5 軸 CNC 高速加工機 DWX 系列,

此新科技使得牙科齒模實驗室與技術人員能夠持續一貫地製作出精準的齒模鑲補產品.

此簡潔的 DWX

系列整合一部大型 CNC

機器所需擁有的全部功能與支援到一部小型的桌上型

5 軸加工機設計上.

它特別適合實驗室研究或辦公室環境下小批量樣品研發與試做使用,

此 DWX 系列

傳遞並實現了研發創新與高速加工的能力.

功能特色:

- 5

把自動換刀刀庫與自動刀長量測器

- 機器操控狀態自動偵測診斷與即時示警功能

- 5-軸同動加工以達成複雜切削能力

- 精密銑削硬蠟, 氧化鋯,

與 壓克力

- 內建集塵托盤方便連接到任何真空集塵系統

- 切削吹氣系統可協助加工困難與較硬材料

- 是建立牙帽(copying),全冠牙帽(

crowns), 牙橋(bridges) 與牙礅(abutments)的理想工具

- 創新的夾持系統可牢固地夾住多樣的材料

- 簡化的操控面板使得操控變得簡單

- 搭配 VisiCam

五軸加工軟體, 提供

5軸實體切削刀具路徑計算與加工模擬,

適合實驗室小批量生產與 5 軸教學.

|

|

|

5-軸同動加工

Capable of 5-軸 simultaneous

machining, the DWX-50 supports the

production of high-quality dental

prosthetics at an affordable price

point. The DWX-50 is designed to

mill on X, Y and Z 軸, rotating

blocks and discs of material 360

degrees in both clockwise and

counterclockwise movements, as well

as tilting materials forward and

backward 20 degrees to support

complex cuts.

|

|

|

5-把直排式自動換刀庫

The five-station Automatic Tool

Changer (ATC) with a tool length

sensor enables you to run multiple

tools for one job or an entire disc

unattended. Instead of inspecting

finished pieces to determine if

everything was milled correctly, the

integrated tool diagnostics feature

will notify you if a tool was broken

prior to completion, resulting in

reduced time and wasted materials.

|

|

|

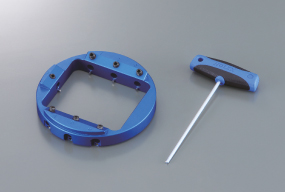

方形材料加工(選配夾具)

| 可承載材料外形 |

方形插銷種類

(小) |

| 可承載材料數目 |

最多 7 支 |

| 可承載材料尺寸 |

載裝 7 支:

10 x 12 x 15 mm |

| 載裝 6 支:

14.5 x 20 x 21 mm |

|

|

|

掌控綴補生產時程

With its unmatched ease of use

and short learning time, the DWX-50

provides a cost-effective solution

that is ideal for dental labs

wishing to take control of the

production process while avoiding

the long lead times and costs

associated with outsourcing.

|

|

開放式架構容易整合各式

3D 掃描機與 CAD/CAM 軟體

A true open architecture system,

the compact DWX-50 integrates with

industry standard 3D scanners,

computers and all popular CAD/CAM

software to provide a very

cost-effective production solution.

Advanced communications tools and

operating features allow the DWX-50

to mill unattended while providing

confidence in the finished product.

|

|

|

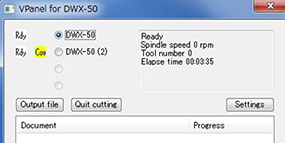

親合力強的使用者操控介面

The DWX-50 features Roland's

Virtual Machine Panel or VPanel for

short. Serving as the main operation

panel for the DWX-50, you can

automatically set up the dental

clamp and quickly set the origin

points from your computer. The

VPanel also provides an easily

accessible hour meter to keep track

of overall machine time for

maintenance purposes.

|

|

|

高品質的材料加工

Ideal for milling wax, zirconia

and PMMA, the DWX-50 is able to cut

materials quickly and with

precision. For maximum flexibility

in choice of materials, the DWX-50

is equipped with universal material

clamps and adaptors that hold and

cut a variety of industry standard

material discs and blocks.

|

|

|

潔淨的銑削區域支援精確銑削

The DWX-50 is equipped with a

built-in air blower that cleans the

ATC magazine and cutting surface of

debris ensuring smooth, error-free

operation. The DWX-50 includes a

vacuum system to remove fine

zirconia dust. The vacuum port is

located in the front of the machine

to connect to and disconnect a

vacuum unit conveniently.

|

|

|

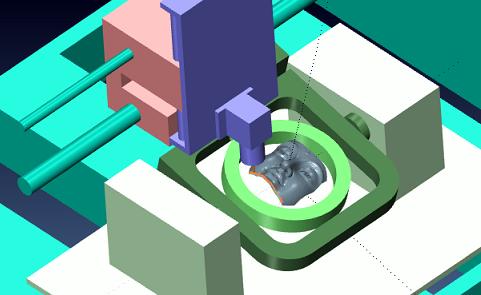

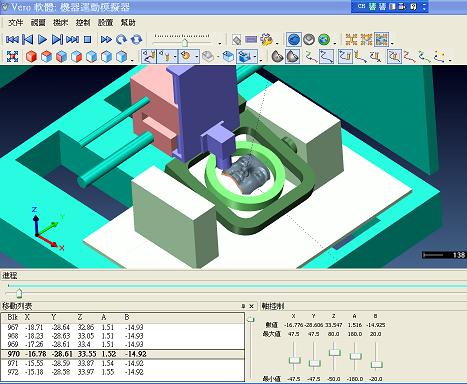

搭配 VisiCad/Cam

五軸加工軟體.提供 3~5

軸刀具路徑產生與實體機械切削模擬. |

|

|

內建 LED

燈光

Designed for low power

consumption, the built-in LED lights

in the DWX-50 allow for easy

monitoring of the work area

throughout the production process.

|

|

|

多重傳撥功能(每台電腦最多可串接控制

4 台 DWX40/50)

DWX-50 提供多工傳撥功能,

只需透過一個 USB 阜,

即可連接最多 4

台機器到一部電腦.

允許實驗室隨著業務量的增加,在增加機器數量時,也能以最低的成本達到產能的提升.

|

|

|

一年保固

Built on more than 20 years of

Roland DG's proven experience in CNC

milling devices, the DWX-50 delivers

advanced features and exceptional

performance for the perfect

combination of innovation and

affordability - all backed by Roland

DG's reliability and legendary

support.

|

|